At FPE, we understand that success for our customers isn’t as simple as using the food processing equipment we provide. In this industry, success is dependent on far more than machinery and food processing equipment parts. It relies on the harmonious relationship between your machines, your people and your support systems.

With that in mind, we have some exciting news. Thanks to a new collaboration with Visual Workplace Australasia, a global partner of the TWI Institute, our customers can now access a range of Training Within Industry (TWI) programs. Keep reading to find out more.

Overview:

- Why FPE is collaborating with Visual Workplace Australasia

- What is Training Within Industry (TWI)?

- Benefits of TWI training

- What a TWI Program could look like for your food processing business

Why FPE is collaborating with Visual Workplace Australasia

Imagine if you went out into your plant, sent all the operators home and then timed how long it took for production to stop. Our bet is you’d time this in minutes, not hours.

Likewise with operational systems; try isolating equipment from a support system (like a central server for example) and time how long it takes for production to stop.

Likely, the biggest variable in the success of your equipment investment will be the people. The mindset, readiness and adaptability of those directly involved with using your new equipment, as well as the people leading the operators, will heavily influence your profitability.

When you invest in new equipment with FPE, what is the likely impact of this upgrade? How big is the change? While FPE provides training on how to use our machines, we don’t specialise in the people and process training necessary to align other aspects of the business with your updated processing line.

But Visual Workplace Australasia does. A TWI Institute global partner, partnering with Visual Workplace Australasia allows us to plug those gaps in terms of the people and systems side of your business development and growth.

Leading change within food processing businesses

How experienced are your leaders at leading change and facilitating growth? How skilled are they in adapting and problem solving? What is the state of your current training system?

What about your support systems, like equipment maintenance or care? In what way might they need to adapt to ensure optimal return on your equipment investment?

At FPE, we see ourselves as much more than just an equipment supplier. We pride ourselves on our extensive customer support. We’re your equipment solutions partner and our ultimate goal is to help you grow your food business.

This is why we’re collaborating with Visual Workplace Australasia.

What is Training Within Industry (TWI)?

Training Within Industry (TWI) was created by the United States Department of War in 1940 to provide consulting services to war-related industries. TWI training continued post-war and was integral to rebuilding industries across Europe.

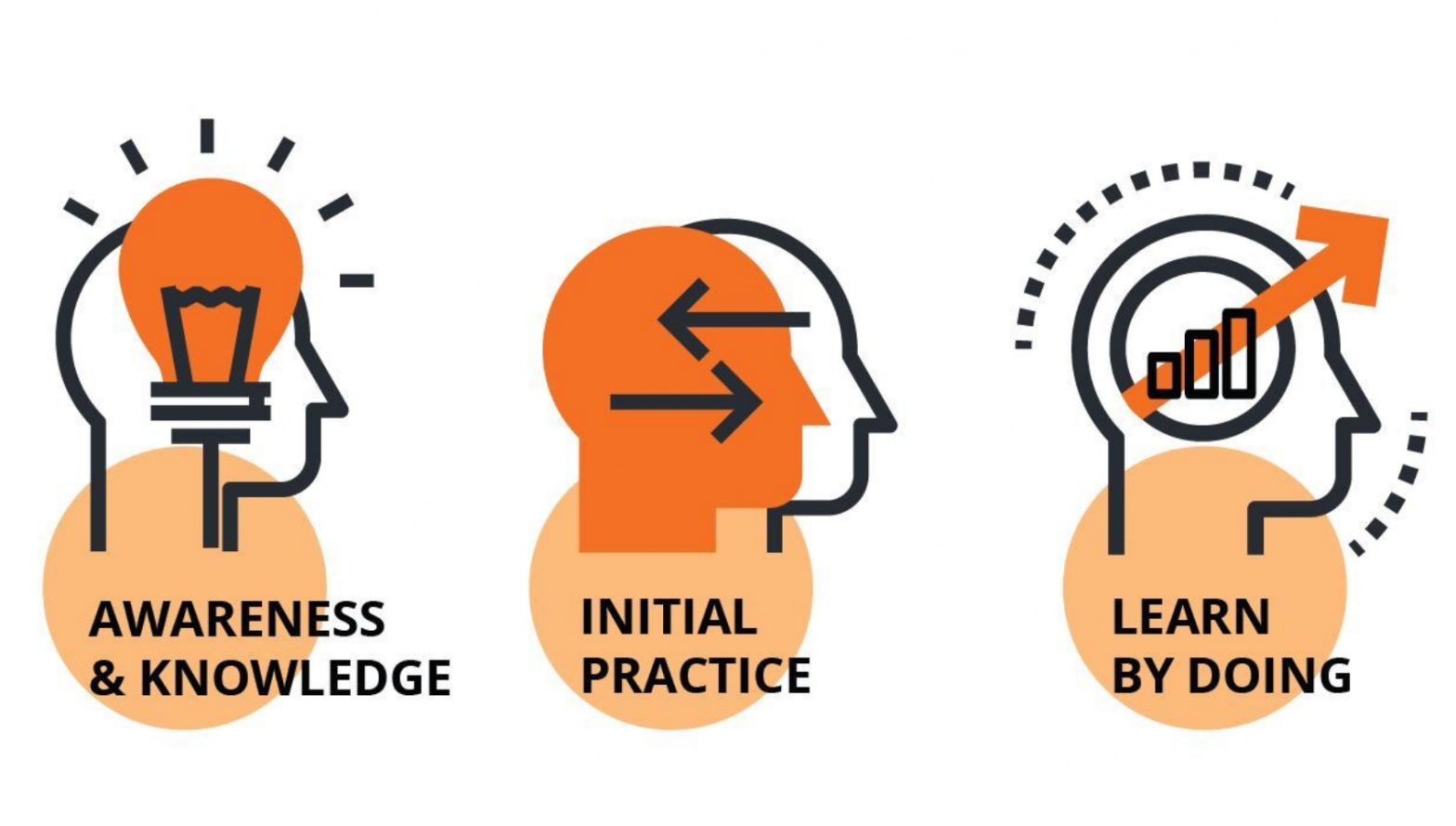

Today, TWI is a “dynamic program of hands-on learning and practice, teaching essential skills for supervisors, team leaders, and anyone who directs the work of others.” (source: TWI Institute)

TWI is responsible for the introduction of kaizen (‘continuous improvement’) to Japanese industry. It’s also an essential element of Lean and continuous improvement programs around the world, including the Toyota Production System.

Benefits of TWI Training

TWI programs have proven success in:

- Generating cooperation and positive employee relations

- Teaching supervisors how to quickly and correctly train employees

- Establishing and maintaining standardised work

- Improving business methodology

- Solving problems efficiently and effectively

- Creating a safe work environment

What a TWI program could look like for your food processing business

Does Visual Workplace Australasia provide workshops on site?

Yes, this is preferred. However, current restrictions have necessitated a shift to approximately 25% on site, 75% live online. Of the 75% live online, 25% is online ‘workshops’ and 75% is mentoring.

Do they provide bespoke programs?

Yes, the programs are very bespoke. The process begins with a Situation Analysis, which consists of lots of open questions, listening and looking. Then a One-Page-Plan is prepared. This is followed by delivery, allowing for adjustments learned along the way.

Is it specifically ‘leader skill development’ for current/future business leaders of the processing plant?

Not always, but nearly always. Generally, there will always be an element of leader skill development in the program.

If you are curious to know more or would like to register your interest, contact the specialist team at Visual Workplace Australasia today. Like what you read? You can also check out the rest of our Resources section for articles on the NoahFace thermal screening kiosk and how to reduce waste in food production.