Effective food depackaging equipment plays a crucial role in reducing food waste, increasing yield and even improving recycling of organic waste, to reduce landfill. Food depackaging machines can recover soft food products from packaging, peels or seeds.

In 2010-11Australia generated around 14 million tonnes of organic waste, with 47% disposed into landfill, according to the Australian Government Department of Climate Change, Energy, the Environment and Water. This contributes to greenhouse gas emissions such as methane from landfill. Sustainable food processing practices aim to reduce food waste while increasing yield and improving quality assurance from the beginning of each food processing workflow.

Overview

- What is food depackaging?

- How does a depackager work?

- Depackaging equipment applications in food processing

- Depackaging machines in food waste management

What is food depackaging?

Food depackaging machines separate the organic content of food from inorganic packaging materials such as plastic, glass and cardboard. Depackaging machines can reduce the wastage of input products in food processing to maximise yield.

Depackagers can be used in food waste processing to increase the recovery of organic food matter from discarded packaging, ensuring organic waste can be composted rather than entering landfill.

How does a depackager work?

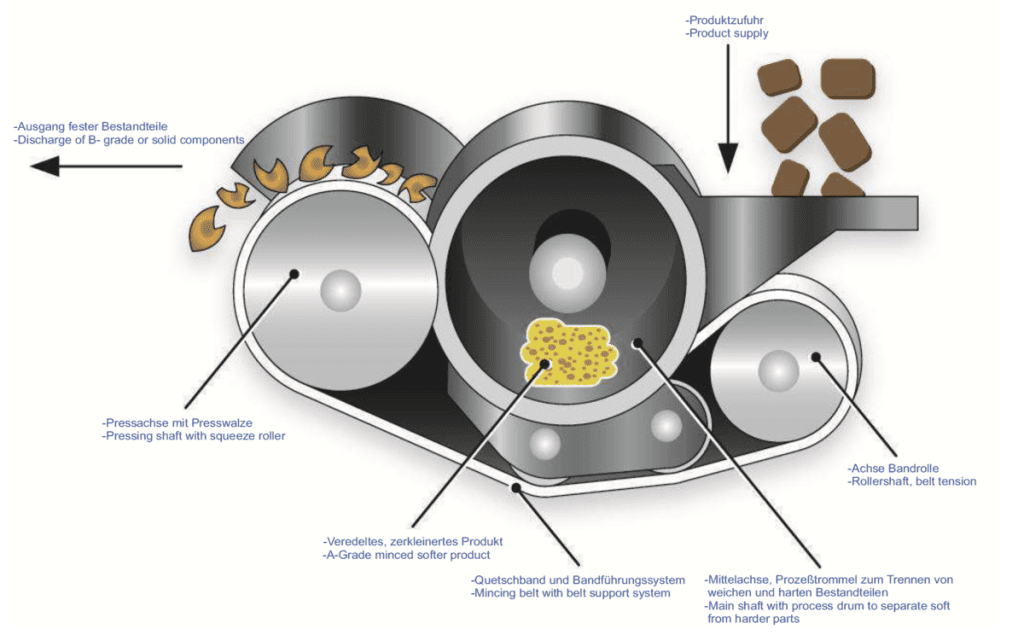

Sepamatic’s depackaging machine is a soft belt separator that can gently separate materials based on their different textures. Hard or solid components are ejected during the process. Soft components pass through a perforated drum and exit via a fixed screw.

The diagram below illustrates how the Sepamatic depackaging machine works to separate solid materials like food packaging from softer food matter.

Depackaging equipment applications in food processing

Depackagers can be used in the food processing industry in various applications to gently separate soft food from unwanted peels, packaging, pulp or other non-desirable parts.

Dairy food depackaging

A soft separator belt depackaging machine can depackage foil-wrapped cheese or remove butter, oil or yoghurt from plastic containers. Depackaging equipment comes in a variety of sizes suitable for use in the baked goods industry or ready meal industry.

Fruit and vegetable food depackaging and soft separating

These machines are suitable for separating and processing fruits like avocado, by gently separating the hard peel and seed from the soft pulp or flesh. The machine can separate the flesh from the skin or seeds in preparation for blending.

Fruits like citrus or any other fruit where the flesh has a softer texture than the peel or rind can be depackaged successfully using this technology to produce convenience foods ready for consumers.

Pet food depackaging and separating

Sepamatic machines can check and ensure that raw, incoming product for pet food is separated from undesirable parts and contaminants.

Depackaging machines in food waste management

Food waste packaging in feedstocks is a potential barrier to efficient processing. Food waste feedstocks contain plastics, paper, cardboard, cans and glass which can cause blockages and abrasions in process equipment and inhibit the effectiveness of digestion processes. To comply with standards for digested products from composting an additional step is required to remove visible plastics using fine screening.

The Waste & Resources Action Programme (WRAP) included Sepamatic’s soft belt separator equipment in a 2009 review of suitable for recovering food waste packaging from feedstocks for composting and anaerobic digestion to improve the fraction for recycling.

Effectively depackaging food waste before processing to remove hard inorganic parts can improve the recovery of waste organic matter. This organic food waste can then be treated using anaerobic digestion or in-vessel composting plants.

Depackaging machines are available from FPE

FPE supplies Sepamatic soft belt separators which are effective depackagers. These machines are available in a range of sizes and levels of automation for standalone use or inline food processing. We can also supply replacement parts and consumables to ensure your depacking machines run smoothly long term.

To learn more about FPE’s depackaging machines, available in Australia and New Zealand, call our friendly team on AU 1800 882 549 or NZ 0800 100 003.

Frequently Asked Questions

How can we reduce food waste in food processing?

Use effective depackaging machines to ensure that you gain maximum yield from incoming products and send less organic food waste into landfill. Eliminating unwanted items using a soft belt separator at the beginning of the food processing workflow reduces product recall, increases customer satisfaction and improves the efficiency of the production line with better quality control up front.

How are depackaging machines used for disposing of food waste?

Depackaging machines in food waste processing remove organic food material from plastics, cardboard, aluminium and other packaging materials. The soft organic food matter can then be processed through composting.

How does a mechanical food depackaging system work?

A mechanical food separation system removes ‘hard’ substances from ‘soft’ food products. Peels, pip, packaging, skin or bone are separated from the soft pulp, meat, dairy or other soft food matter using a gentle mechanical belt system. Once unwanted contaminants are removed the soft food material moves to the next step in the food processing production line.

You may also like:

- Automation in Food Manufacturing: Spotlight on BCH

- Streamline Your Wet Food Manufacturing Process With DCN

- What Is An Automated Material Handling System?

References: Review of Food Waste Depackaging Equipment, April 2009, ISBN 1-84405-412-8