At FPE, we’ve been working with the Australian meat industry since 1983. In that time, we’ve provided specialist expertise and various meat processing equipment, from butchery tools to slicers, dicers and everything in between. As the industry has evolved, one thing has remained the same: our commitment to partner with only the very best manufacturers. Today we’d like to focus on Magurit and their latest innovation in frozen meat cutting/grinding, the RECUT series.

Overview:

- What is the Magurit Recut?

- Who is the Magurit Recut technology for?

- Common meat grinding challenges

- How is the Recut different from other meat grinding machines?

What is the Magurit Recut 324?

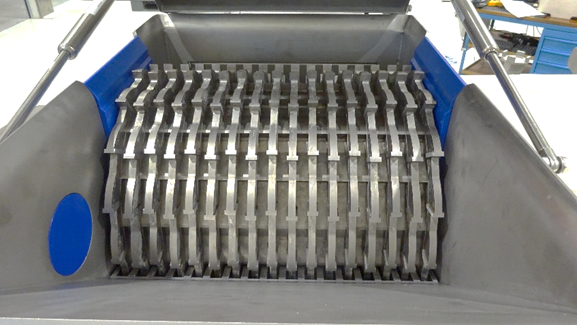

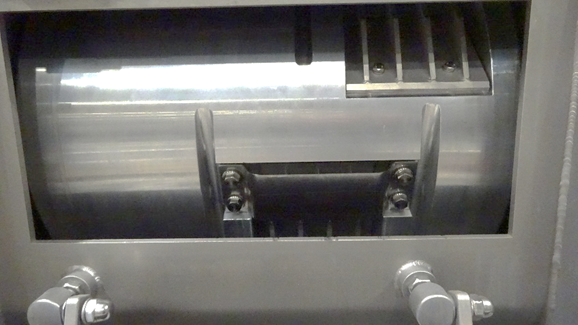

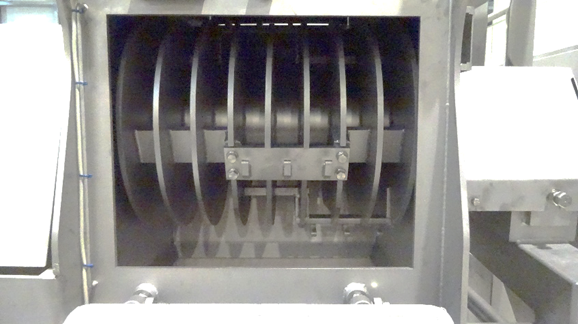

The Recut 324 is a frozen meat processing machine for finely ground meat applications. As the latest innovation from meat cutting specialists Magurit, this automatic meat grinder is capable of cutting frozen product by fast rotating punch knives into small pieces without destruction of the natural cell structure of the raw material.

Magurit Recut is a brand new technology for the very small cutting of product. Frozen raw materials such as meat, poultry, fish or fruit and vegetables are cut to a minimum particle size of 8mm. Loose IQF products can be cut accordingly with the Recut 2D, and for block-frozen raw material we offer the Recut 3D. A Magurit frozen block cutter of the Starcutter or Precut series functions as a pre-cutter, so the desired final piece size is subsequently achieved by the extra-sharp blades of the Recut.

Who is the Magurit Recut series for?

The Recut series is ideal for any food producers making the following foods:

- Ground and minced meat

- Emulsified products, e.g. sausages

- Formed meat, e.g. nuggets

Common meat grinding challenges

Usually, the first step for processors is to feed frozen meat-blocks into a frozen block grinder, with subsequent CO2 injection for mixing, due to product temperature increase during grinding.

There are a number of problems with this process:

- Destruction of raw product

- Energy costs between 90 and 150 HP

- Costly CO2 injection

Until now, Magurit has mainly offered 2D rotation cutters as an alternative to frozen block grinders, which left the resulting pieces of ground meat too large.

How is the Recut 324/326 different from other meat grinding machines?

The Recut machines are an innovation in meat grinding, boasting the following advantages:

- Works at -18°C / 0°F

- Very little product destruction

- No metal shearing / abrasion

- Very low energy consumption

- 344 + 324 = 5.000 lbs / h, only 24 KW

- 328 + 326 = 15.000 lbs / h, only 33.5 KW

- Reduced usage of CO2 / cooling gases in mixing process

- Better product appearance / colour / bite

- Recut can also be equipped with different cutting drums for flaking or loosening lumped frozen products

In short, the Recut 324 and 326 represent the next evolution in cutting for industrial applications that require a very small cutting result.

If you’d like further details either about the Recut 324, 326 or any of Magurit’s other industrial meat cutting equipment, please don’t hesitate to contact our friendly team on AUS 1800 882 549 or NZ 0800 100 003.