There’s a new innovation available from AMTek Microwaves that we’re very excited to now offer at FPE. Introducing the AMTek automated conveyor belt washer, which saves hours of hand pressure washing and can be used with absolutely any conveyor belt system. Read on to find out about its state-of-the-art features, the sizes available and more.

Overview:

- What is the AMTek conveyor belt washer?

- Benefits of the automated conveyor belt washer

- How does a conveyor belt washer work?

- AMTek conveyor belt washer components

- Available sizes and add-ons

- How to order

What is the AMTek conveyor belt washer?

The AMTek conveyor belt washer system is a complete, universal, automated washing system for a wide variety of food processing equipment conveyor belt.

The AMTek belt washers have a programmable recipe function that enables the operator to walk away and let the washing program run. This will also dial in chemical and water usage to conserve both where possible.

Benefits of the automated conveyor belt washer

- Easy HACCP compliance

- Huge time and manual pressure-washing savings

- Huge energy savings over compressed air blow-off methods

- No air pressure fluctuations

- Natural heat of compression assists in the drying process

- Optional HEPA filter integration

- Easily integrated with existing conveyor lines

- Can be located on mezzanine away from process area[GN1]

- Water and chemical savings compared to hand washing, thanks to metered dosing system

How does a conveyor belt washer work?

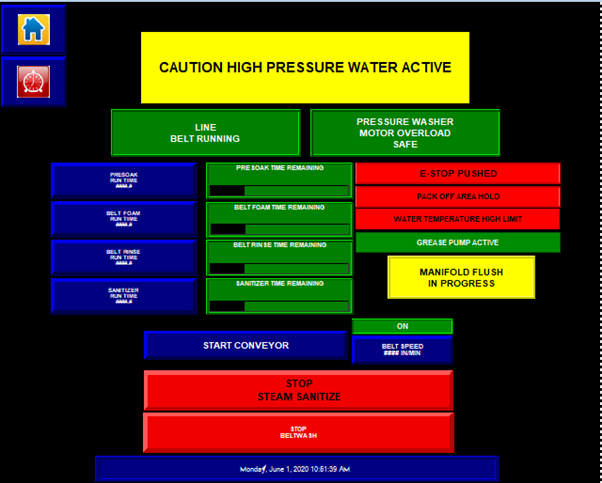

The belt washer function is controlled by a sequential timer program within the control Programmable Logic Controller (PLC)[2] [GN3] [4] . To access the belt wash control, simply flip the key switch on the front of the control cabinet from “Run” to “Clean”.

The following sequence is performed automatically as part of the belt wash cycle:

- City water purge (clear the system)

- Low pressure city water presoak

- Foam grease and residue release

- High pressure city water rinse removes foam and sonic blower dries belt

- Sanitiser applied – end of belt cleaning

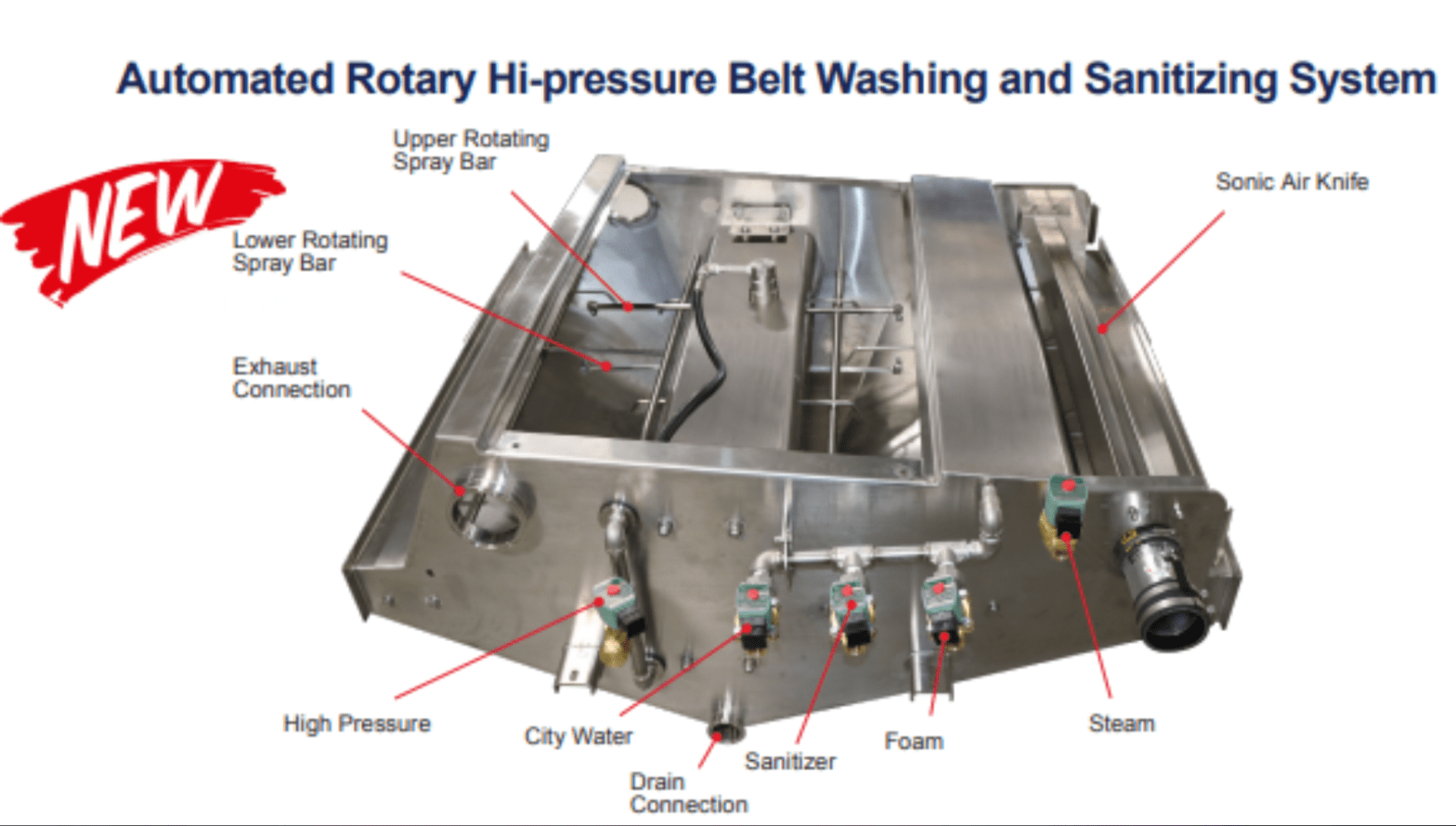

AMTek conveyor belt washer components

The main components of the belt washer system are:

- PLC and Human Machine Interface (HMI)[6] [GN7] [8]

- Belt washer assembly and city water solenoid valve

- High pressure water solenoid valve

- Pressure washer assembly – optional

- Foaming manifold and solenoid valve – optional

- Sanitiser manifold and solenoid valve – optional

- Steam manifold and solenoid valve – optional

Belt washer assembly

Constructed of 304 stainless material, the belt washer has a PLC controlled automated wash cycle with water flow solenoid valves. Belt drying is performed with a high velocity stainless steel air knife. A stainless drain sump collects wash and rinse water.

Available in single or dual belt washer systems, the AB PLC control assembly allows for automated control of the washer assembly with a PanelView 7” Plus 7 HMI[GN9] touchscreen display.

Features

- Stainless steel housing

- Designed to deliver an automatic wash cycle of the system conveyor belt

- Programmable for either a timed function or written recipe for the predetermined number of belt revolutions

- Top access lid removes for easy cleaning of the interior of the belt washer

- Solenoid valves supplied rated to 1,500 psi/103 bar supply water pressure

- Four stainless steel high pressure rotating spray bars installed to cover the entire belt width on both sides of belt, for continuous belt cleaning

- Spray nozzles installed and sized for the customer’s supplied water pressure

- Exhaust connection available of 4” [102 mm] Tri-Clamp for spray mist removal if required

- 1.5” [38 mm] Tri-Clamp, on sumped floor, for customer connection on waste water removal

High pressure pump

The high pressure pump assembly includes:

- TEFC drive motor

- Tempering 1000 PSI (68 bar) pump (for cooking lines 1000-1200 PSI / 68-82 bar is recommended)

- Pressure gauge

- Assembly mounted on stainless skid

Available sizes and add-ons

Sizes available

- 24” [610mm] Wide Belt Washer Assembly

- 36” [914mm] Wide Belt Washer Assembly

- 42” [1067mm] Wide Belt Washer Assembly

- 48” [1219mm] Wide Belt Washer Assembly

- 52” [1321mm] Wide Belt Washer Assembly

- 60” [1524mm] Wide Belt Washer Assembly

If not in the standard belt width range, wash systems can be made to your belt specification. Support frame with levelling feet also available[GN10] .

Optional foam & sanitiser assembly

- A manifold assembly addition to the washer housing assembly, this is for the use of foam and sanitiser applications to the conveyor belt materials.

- Includes low pressure solenoid valves for the individual supplies of foam, sanitiser, and rinse water to the manifold assembly.

Optional sonic blower & HEPA filter

Optional HEPA filters provide clean filtered air to the air knife, keeping your process completely sanitary.

- High velocity blower and air knife assembly for removal of wash water immediately after the belt washing process

- Sonic high velocity blower assembly with silencer/filter assembly

- Wash-down rated models are available on the motor assemblies, as well as voltage specific builds

- Blower model and HP will be sized to provide adequate air flow to the water removal air knife assembly

How to order

Contact the team at FPE today on 1800 882 549 (Australia) and 0800 100 003 (New Zealand) to enquire about the AMTek universal conveyor belt washer system. If there are particular add-ons you’re interested in, do let us know. We would also need to confirm installation and mounting placement to your conveyor belt system, as they can be made to your requirements.

Please note, FPE also supplies a wide range of food processing cleaning equipment by industry leaders Elpress, as well as sanitising conveyors by SYSPAL.

You might also like:

- Sanitation & Cleaning In Food Processing Industry

- How to Clean a Hygiene Station

- Food Safety Monitoring Processes & Equipment