Food safety monitoring is critical at every step in the food manufacturing process, from raw ingredients to the final packaging.

Ensure food safety monitoring at each step of the food processing workflow, particularly where there is the potential for new contaminants to enter, to achieve higher quality output and reduced recall. To do this, we recommend inspecting, cleaning and sanitising, checking and documenting your process. This will set your food processing operation up for continual improvement in HACCP.

Overview

We thank all of you for your support during this time and encourage you to reach out to us if there’s anything we can assist you with.

HACCP & food safety plans

The current COVID-19 virus pandemic is a stark reminder for us all of how easy pathogens can transfer from human to human, but also from humans to other surfaces.

All food businesses should be working hard to re-evaluate their food safety monitoring processes and applications of the HACCP Guidelines at this time.

HACCP is the internationally recognised system used to identify and manage “hazards” – reducing the risks of food contamination across the whole production process.

As early as the 1960s, HACCP was created in an effort to control biological, chemical and physical hazards in the food production process.

HACCP principles

HACCP stands for Hazard Analysis Critical Control Point and is made up of seven principles:

- Conduct a hazard analysis

- Identify critical control points

- Establish critical limits

- Establish monitoring procedures

- Establish corrective actions

- Establish verification procedures

- Establish record-keeping procedures

It’s important that these principles are used at every point in the food production process, from growing and farming to distribution and consumption.

The Coronavirus crisis is a wake-up call for the entire food industry, but perhaps in particular for those involved in agricultural and horticultural activities, where viruses can spread easily, causing loss of crops and short shelf-life of products.

Four safety monitoring processes

There are numerous ways to implement HACCP and other food safety monitoring processes. Here are 4 that you can do right away with the help of FPE:

- Inspect for contamination

- Separate high and low care areas

- Clean and sanitise throughout the processing workflow

- Monitor at each step of the process

Automating food safety reduces risk and ensures you meet the expectations of customers, with in-built record-keeping systems to monitor efficiency and the final product.

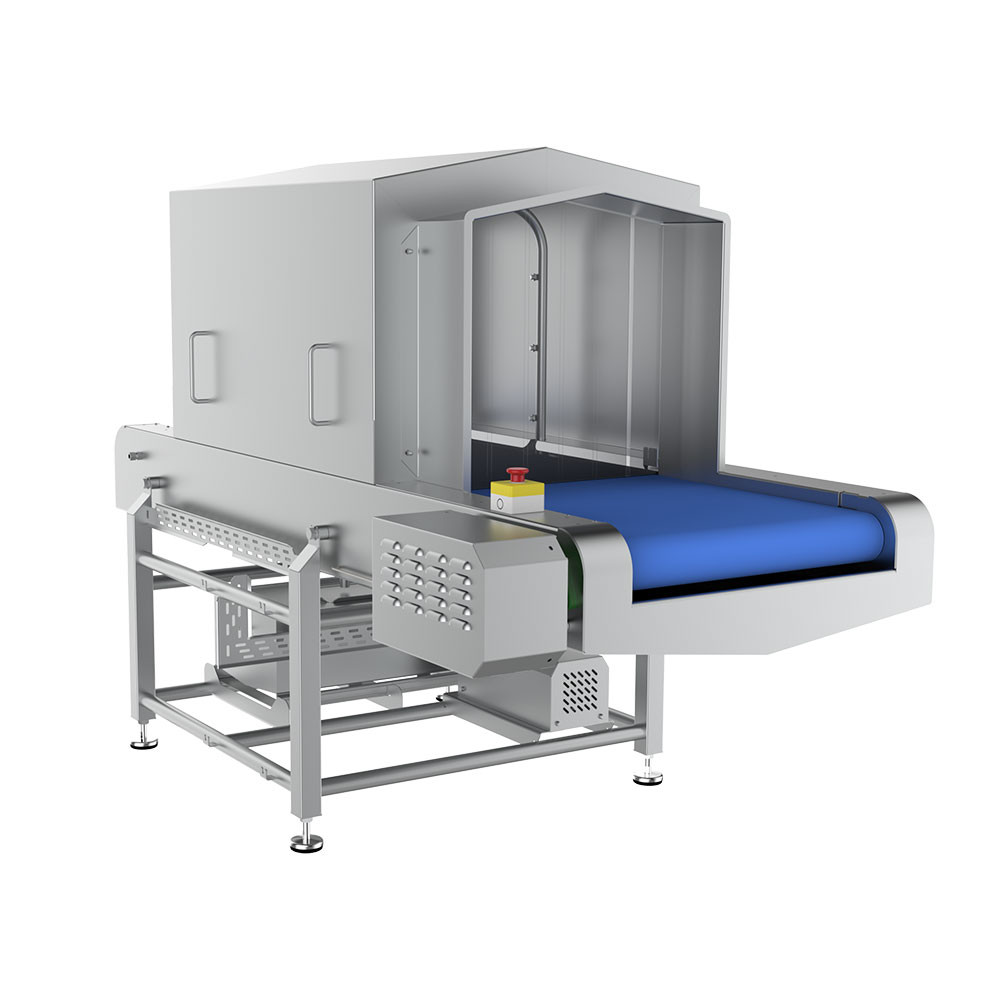

1. X-ray inspection of incoming and outgoing product.

X-ray inspection of incoming ingredients and outgoing products differentiates organic and inorganic matter, ensuring that contaminants, including small fragments of bone, are detected.

Inspection can be implemented for incoming ingredients to ensure that any contaminants are removed before the process begins. Then, once the final product is packaged and ready to ship, a final inspection ensures that each item is free from foreign particles, reducing the likelihood of product recall. FPE’s Eagle X-Ray machine customers have access to a 24-hour helpline to provide total peace of mind.

2. Separate high and low care areas

The BRC Global Standard for Food Safety requires there to be physical segregation between low and high care areas.

SYSPAL Sanitising Conveyors make meeting this requirement easy. These machines allow the operator to pass utensils, raw ingredients (still in their packaging) and equipment through the segregation barrier between low and high care areas in absolute safety.

These machines make processing plants compliant, but they’re also essential for eliminating the risk of cross-contamination between production areas.

3. Clean and sanitise at each step in the process

Cleaning and sanitising in meat processing and in fact, in any food production industry is essential to ensure food safety.

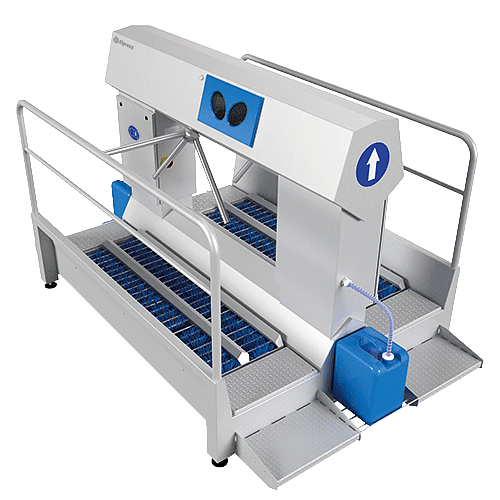

Effective food safety culture encompasses employees who work directly with food during the process. Before entering the processing room, employees should take appropriate precautions to ensure food safety and prevent accidental contamination.

Elpress industry-leading industrial hygiene stations minimise the risk of transmission of pathogens in food processing environments via human contact.

Elpress manufacture and supply hygienic entrances (or “hygiene locks”) and washroom solutions implemented by food processors globally.

Implement an effective pallet cleaning procedure using a checklist to ensure no steps are missed, and use mechanical handling equipment that includes wash stands for easy and automated cleaning.

Monitor each step of the process

Setting quality assurance KPIs for food safety and monitoring processes enables continual improvement in food safety as well as overall yield and efficiency.

Christy Draus, Eagle Marketing Manager, says:

“Smarter food safety is data-driven, …those in the food chain – including growers/farmers, manufacturers, retailers and foodservice operators are taking advantage of (or should take advantage of) technologies that allow for greater traceability and quicker responses to suspected illnesses or injuries.”

All Eagle inspection machines through FPE come with the option of HACCP compliance software, improving the functionality, reporting and quality assurance traceability of Eagle’s X-Ray systems.

Establish effective food safety processes with equipment from FPE

FPE is a proud supplier of Eagle, SYSPAL and Elpress machines because they represent the industry standard in safe, hygienic food manufacturing.When you order with FPE, you receive comprehensive support, including spare parts supply, equipment training and maintenance. Contact FPE today to learn more about food safety monitoring processes and equipment for your plant.