Every food processing business has their own unique needs, and with ever-changing consumer behaviour, it’s important to have a streamlined and agile production line. This is why FPE works hard to ensure you have the cutting edge technology you need to meet all of your food production needs.

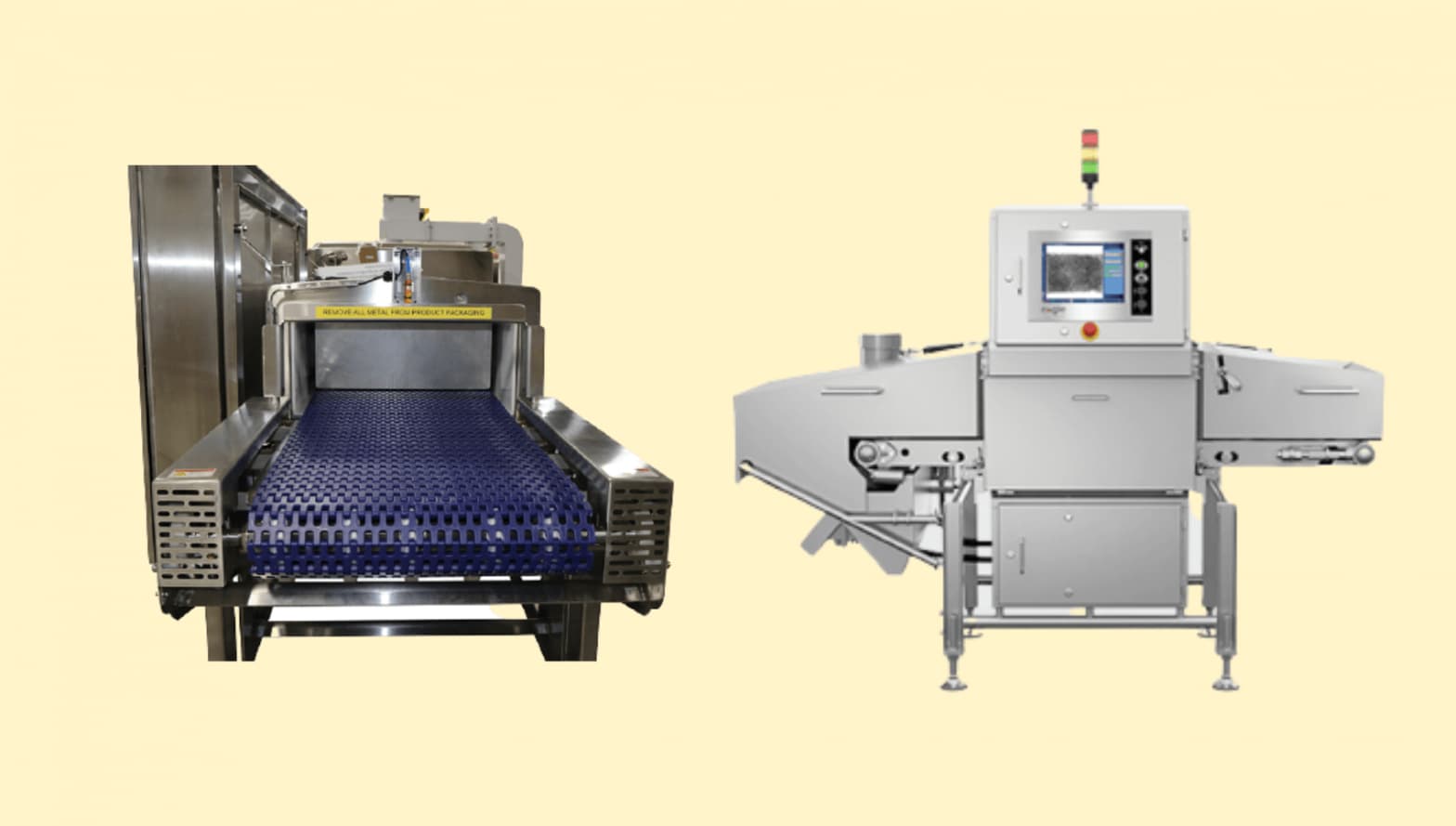

We offer an outstanding selection of high quality meat processing plant equipment, meaning you can combine our meat processing equipment to streamline your business. The Eagle X-Ray Dual Energy and the AMTek Microwave, provided exclusively by FPE, are the perfect way to combine processing equipment to keep your business efficient and agile.

Overview

- Be prepared to change with consumer demand

- Create an agile production line

- Eagle X-Ray Dual Energy

- AMTek Microwaves

- 3 reasons why Eagle X-Ray and AMTek technology work so well together

Be prepared to change with consumer demand

When working in food processing, it’s important to note ever-changing consumer demand. For example, varying types of pies, sausages and deli meats come in and out of favour and it is our job to meet these consumer demands. In addition to this, the public is increasingly interested in the macros of their food and the protein breakdowns.

This swing in trends shows the need to have a production line that is equipped to adapt to major trends. For example, are different types of pie becoming more popular? What are the minimum protein levels required? The Eagle X-Ray fat analysis equipment can monitor the protein levels ensuring you meet client demand and maximise profitability.

Having these insights into the products you’re serving will enable you to establish yourself as a sustainable business that understands its consumer.

Create an agile production line with complementary meat processing plant equipment

When working to your business and industries’ unique needs, it pays to obtain meat processing plant equipment that works seamlessly together to help you meet consumer demands. With our long history working with the meat industry, we’ve found that the Eagle X-Ray Dual Energy machines and AMTek Microwaves work particularly well together.

By combining the use of Eagle X-Ray food inspection systems with the AMTek Microwaves, you’re setting your meat processing line up for success.

Eagle X-Ray Dual Energy

The use of the Eagle X-Ray Dual Energy in your food processing business is truly revolutionary as the Absorptiometry (DEXA) technology allows you to discriminate between fat and lean portions of meat, providing chemical lean testing measurements to better than +/- 1CL accuracy. Eagle’s FA3 Series will check your meat with a:

- Fat analysis

- Contamination detection

- Mass measurement

- Protein analysis

- Moisture analysis

AMTek Microwaves

Able to effectively temper your products in a few hours instead of days, AMTek Microwaves allow you to work efficiently and intelligently.

Whilst microwaves in the food industry have historically been controversial, they have numerous benefits when it comes to industrial food processing and meat thawing specifically, such as:

- It’s faster than conventional heating, reducing processing times

- Nutrient retention is high, improving product quality

- It allows for precise process control and optimal energy usage

- It can be used post-packaging, retaining moisture content

- It’s a clean process

3 reasons why Eagle X-Ray and AMTek technology work so well together

1. Saves time

While other methods of fat analysis are limited to boneless, ground meat, the Eagle X-Ray system can also inspect fresh, frozen, bulk, blended meat or meat packaged in cartons. The technology is not affected by freeze and thaw plant conditions, foil or metallised film packaging or meat conductivity.

This means you can begin the process before you start your thawing process with AMTek – saving you hours, or even days.

2. Eliminates waste

Incorporating efficient and repeatable techniques for fat analysis, chemical lean testing and meat tempering is an easy way to reduce any unnecessary losses your business incurs through inaccuracy.

Not only will these analysis and tempering combinations maximise your yields, they’ll also improve product quality in every batch by reducing drip loss.

3. Precision

You’ll always get precise temperature control and consistent meat, this ensures your product is within the required ranges for subsequent grinding, slicing, forming and moulding before packaging and shipping.Whether you’re looking to combine the Eagle X-ray with the AMTek Microwave or have your eye on any other food processing equipment, FPE has you covered. When you order with FPE, the food processing experts, you’ll receive comprehensive customer support, including spare parts supply, equipment training and maintenance. Contact FPE today to learn more about our wide range of meat processing plant equipment, perfect for your food company.

Whether you’re looking to combine the Eagle X-ray with the AMTek Microwave or have your eye on any other food processing equipment, FPE has you covered. When you order with FPE, the food processing experts, you’ll receive comprehensive customer support, including spare parts supply, equipment training and maintenance. Contact FPE today to learn more about our wide range of meat processing plant equipment, perfect for your food company.