Food processors handle hundreds of pallets a day as part of normal food processing, storing and distribution activities. As part of a comprehensive HACCP plan, ensuring pallets are effectively cleaned is an essential component of health and safety procedures. Not only do improper cleaning processes pose risks in terms of public health, they’re also detrimental to an efficient and streamlined processing plant. So read on to learn how to optimise your pallet cleaning procedure and get a handy checklist for printing.

Overview:

- Importance of washing pallets

- Can you pressure wash pallets?

- How to optimise your pallet cleaning procedure

- Pallet cleaning checklist

Importance of washing pallets

The importance of clean and sanitised pallets cannot be overstated. Any contamination due to poorly washed pallets can result in entire shipments being lost, which has a huge impact on the bottom line and potentially also brand reputation.

In addition to general dust, dirt and grime build up, product can be contaminated by whatever was stored or transported on the pallets previously. For example, raw meat can contaminate cooked product if the pallets used to move or store them haven’t been properly washed and sanitised in between times. This has the potential to make end consumers very sick.

Campylobacter is the most common cause of foodborne illness in Australia; over 3200 people were hospitalised with it in 2014. As food processors, a safe and efficient pallet cleaning procedure is critical to the business’ overall health and safety.

Not only is there an obvious safety benefit to proper pallet cleaning procedures, but if you use a specially-designed pallet washing system, like those from Elpress, there’s also an economic and environmental benefit too. As a food processor, if you’re washing lots of pallets and/or crates on a daily basis, an industrial washing machine can provide you with a nice saving in energy costs, water costs and therefore operating costs.

Can you pressure wash pallets?

Yes, you can pressure wash plastic pallets. However, it’s important to ensure your pressure washer is right for the job. Not all pressure washers are suitable for use with hot water at a sufficient temperature for killing bacteria. That’s why we recommend that food processors use an industrial crate washer instead.

How to optimise your pallet cleaning procedure with Elpress

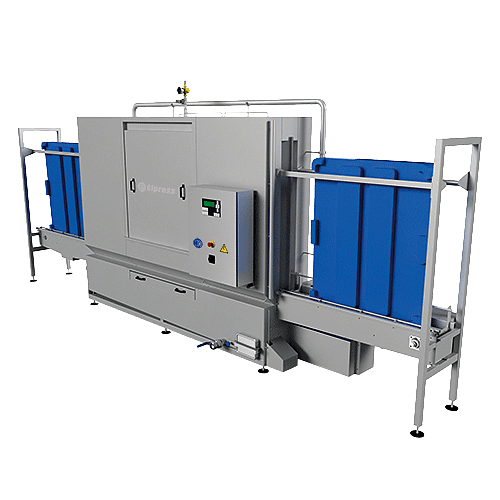

Elpress’s pallet washing machines execute a fully automated, end-to-end pallet cleaning procedure in one compact system. Capable of washing dozens of pallets every hour, the system features a wash tunnel with spray bars and guiding, which keeps the pallets in the right position while they are cleaned.

In the main wash zone the pallets are cleaned and the dirt is removed. The spraying pattern of the nozzles is configured to achieve maximum cleaning results. They are supplied with water by a powerful and energy efficient pump.

In the after rinse zone the pallets are rinsed with fresh water. Any residual detergent will be removed. To achieve this, the rinsing bow is directly connected to the fresh water supply.

Pallet cleaning checklist

This pallet cleaning checklist will help to communicate pallet cleaning procedure best practices to your team. Feel free to download the pdf here for printing.

How to order

Contact the team at FPE today on 1800 882 549 (Australia) and 0800 100 003 (New Zealand) to enquire about Elpress pallet washers. We would need to confirm installation and mounting placement for your system, as they can be made to your requirements.Please note, FPE supplies other industrial washing systems like AMTek’s universal conveyor belt washer, sanitising conveyors by SYSPAL, as well as the full range of Elpress industrial cleaning equipment.