For food processors in Australia and New Zealand, it’s important to stay up-to-date with the latest developments in the industry. Taking the time to research what’s new in food technology and manufacturing every now and then could equate to major business gains in terms of improved safety, efficiency and product quality.

In this article, we’ll look at how technology is transforming the food industry. Then, we’re going to shine the spotlight on two food processing equipment manufacturers that are leading the way in their specialist fields. Want to know what’s new in food technology and manufacturing? Keep reading to find out…

Overview:

How technology is transforming the food industry

Food technology and clever food manufacturing could hold the secret to many major global issues. There are probably close to 8 billion people in the world right now, which means there’s a higher demand for food each year. By using technology to improve food processing, we can improve food’s shelf life, safety, accessibility and efficiency of production.

This isn’t just our view. According to a recent report from ING, technology is dramatically improving food manufacturers’ ability to produce food more efficiently for a growing world population.

What’s new in food technology and manufacturing

Microwave tempering from AMTek

Picture the scene (you probably don’t have to try very hard):

You have an enormous amount of frozen product to prepare for processing. So of course, you have huge rooms full of boxes – just sitting there, thawing out. How long have you got to wait for them to be at the right temperature? Too long, right?

AMTek Microwave systems are a revolutionary new way to handle tempering frozen meat and other products. Their tempering machines use microwave technology to thaw product in minutes instead of days. Imagine what that could do for your processing times.

These enormous microwave ovens eliminate the need for tempering rooms completely. Just think what you could do with all that extra space! Microwave tempering also enables you to have precise control of product temperatures, minimising drip loss and ensuring ingredients are efficiently brought to within the required limits for subsequent slicing, grinding, forming, or moulding.

In fact, when it comes to what’s new in food technology and manufacturing, there are few things more impressive than AMTek’s automatic tempering machines. Whether you have to thaw frozen blocks of meat, fruit pulp, or vegetable sauce, these food processing machines will transform your operations.

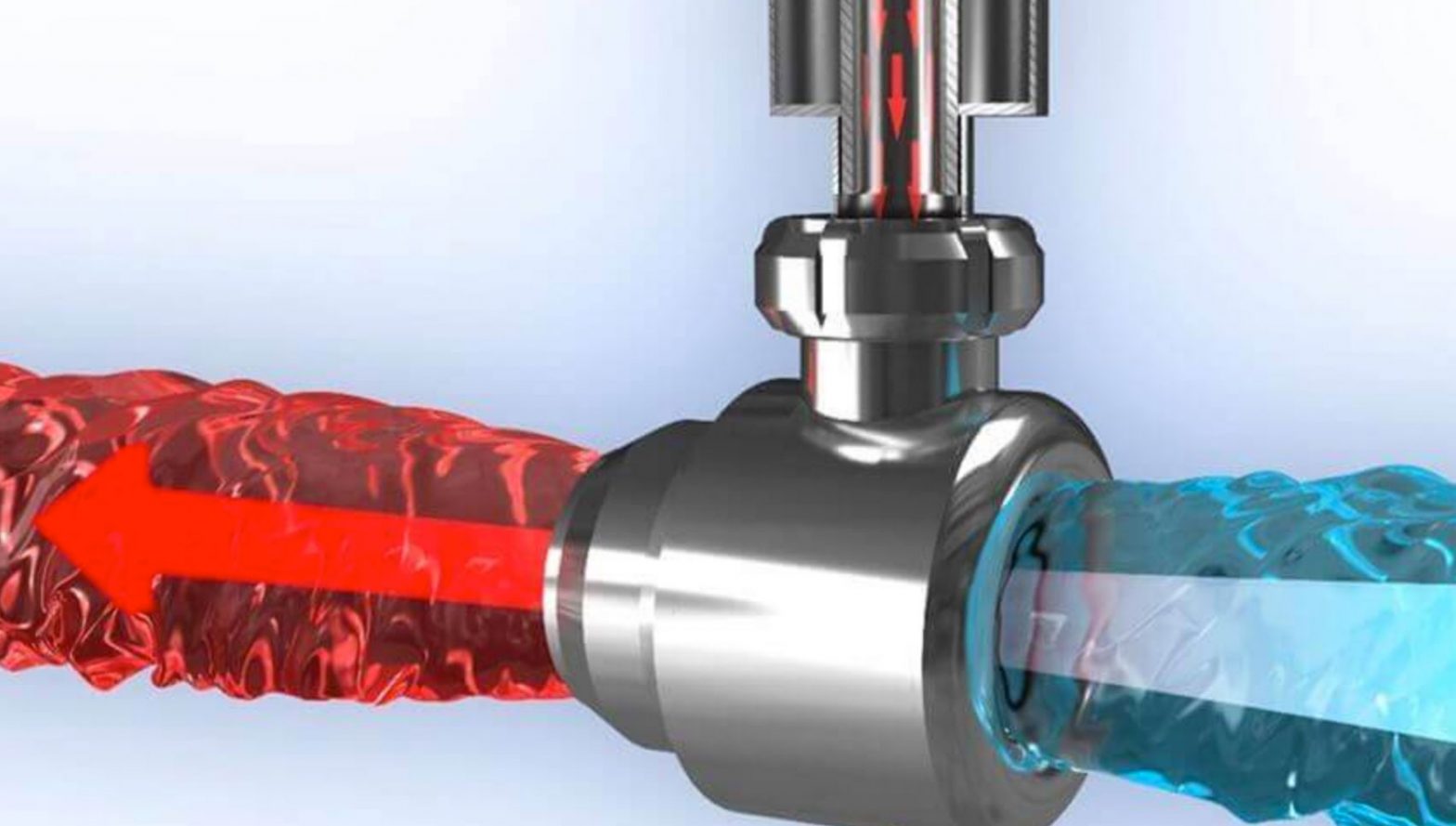

Jet Cook technology

Jet Cook Steam Infusion technology comes from DC Norris. It delivers fast, flexible and efficient liquid processing that includes homogenising, emulsifying, entraining, pumping and heating.

It’s called “jet cook” because it’s fast. Using industrial cooking equipment like this will result in:

- Reduced processing times

- Reduced labour

- Reduced energy

- Reduced burn-on

- Reduced starches and

hydrochlorides - Reduced salt

- Reduced oil/fat

- Reduced clean-down time

- Reduced cleaning fluids

- Reduced wastewater for your

business

That’s a lot of reductions!

Processors using this food technology can also expect improved finished product quality, improved flavours and textures and improved product throughput – just to name a few.

Recipe Manager from DCN

Recipe Manager is another new innovation from DCN. This piece of software allows processors to store their recipes and reopen them again with one touch of a button. But this technology is capable of so much more than just saving recipes. Intelligent features include:

- Ingredient listings

- Step–by–step procedural recipes

- User access security with all recipes stored to a relational database.

- Full records of kettle yields

- Bar code identification from preparation through to packaging

- HACCP controls

Ultimately, Recipe Manager means efficiency and consistency, regardless of who your cook chill equipment operators are.

Microwave tempering, Jet Cook Steam Infusion and Recipe Manager are just three innovative tools currently transforming the food processing industry. If you want to find out more about what’s new in food technology and manufacturing, or to discuss placing an order, contact FPE today. You can also check out the rest of our Resources section for articles on sustainable food manufacturing, food safety monitoring processes, cook-chill products and much more!